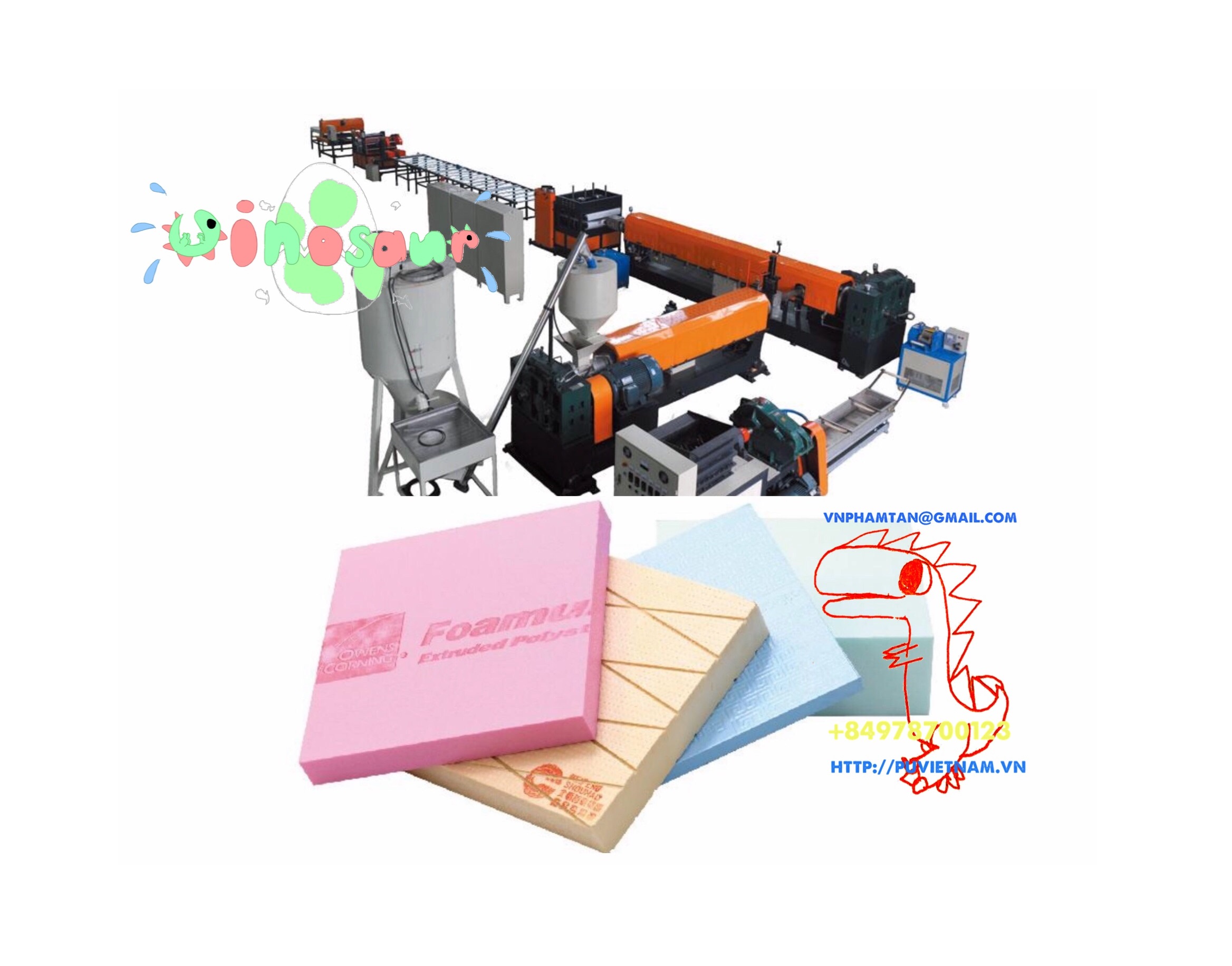

Dây chuyền đúc xốp cách nhiệt XPS công nghệ F22

|

Việt Nguyên Co.,Ltd chuyên cung cấp dây chuyền sản xuất tấm xốp XPS công nghệ CO2 hoặc HCFC F22.

We are pleased to quote according to our enclosed General Terms and Conditions of Supply as follows.

1, We offer 1 years warranty period for all of our machine. 2,Our services will include factory process designing, equipment Installation coaching, testing, commissioning and training for your operation staffs. 3, we provide the whole series of Chinese specification and English Reference books. 4,Factory area: 60m(L)*3m(W)*4m(H) 2 Works MJS-900 XPS LINE TECHNICAL AGREEMENT PRODUCT SPECIFICATION: WIDTH : 600-900MM THICKNESS: 30-80MM OUTPUT CAPACITY: MORE THAN 180 M3 PER DAY(24 HOURS) SPECIFIC GRAVITY: 28-42KG/M3. MATERIAL: PS (BASF foam grade: GPPS158K) FOAM AGENCY: F22(Freon)

Video đúc tấm xốp XPS

I、SUPPLY RANGE: 1、MJX135 Single screw extruder, model: MJX165 One set 2、MJX150 Single screw extruder, model: MJX200 One set 3、Hydraulic screen -exchanger One set 4、Spiral hopper and mixer, model: 1 T/h One set 5、1000×1600 Flatting mill, model: 1000×1600 One set 6、First haul-off unit One set 7、Longitudinal cutting machine One set 8、Second haul-off unit One set 9、Cross cutting machine One set 10、Cooling roller shelf One set 11、Stacker and transmission unit One set each 12、Die Two sets 13、Controlling cabinet for main extruder One unit 14、Controlling cabinet for downstream equipment One set 15、Temperature controller for die One set 16、Foam agent injection system One set 17、Auxiliary equipment 18、List of spare parts

Ⅱ、TECHNICAL CONFIGURATION 1. MJX165 Single screw extruder, model: MJX165 The material of the screw and the barrel is 38CrMoAlA, nitrided. The ratio of length and diameter is 30:1. 1.1 The motor power is 90Kw.AC motor, made by Xi’an SIMO, rotation speed: 1500RPM. 1.2 The barrel is cooled by blower fan. Heating circles are made of mica-stainless steel. There should be a gap at the heating circle of the injection aperture for the foaming agent. The water jacket adopts the integral type,equipped with inner bush. 1.3 The gearbox is of model 315. Its gear is smoothly grinded and carbonized. It specializes in low noise, long service life and reliable usage. It is equipped with the oil-water heat exchanger, made in Jiangyin Gearbox factory. 1.4 The connection mode of motor with gearbox: horizontal, direct connection, on the left. 1.5 There is rail of integral type, flat on one side and triangle on the other side. 1.6 MJS165 maximum output is 320Kg/h.

2、MJS 200 Single screw extruder, model: MJS 200 2.1、The material of the screw and the barrel is 38CrMoAlA, nitrided, nitriding depth is 0.5~0.7mm. screw hardness is above HV740, barrel hardness is above HV940. 2.2、The motor power is 75Kw, AC motor, made by Xi’an Simo. The rotation speed is 1500RPM. 2.3 The barrel is cooled by water, heater is made out of ceramics-stainless steel. 2.4、The gearbox is of special model 375 (the speed ratio 50:1), made in Jiangyin, Jiangyin gearbox factory. Its gear is smoothly grinded and carbonized. It specializes in low noise, long service life and reliable usage. 2.5、The motor and gearbox are connected directly. 2.6、The gearbox is equipped with the oil-water heat exchanger to cool the lubricant. 2.7、The extruder is directly fixed to the ground. 2.8、There are two zones respectively for the water distributing pipe and water collection pipe to insure temperature control.

3、Hydraulic screen -exchanger 3.1、This part consists of screen-exchanging plate, hydraulic station, power storage unit and motor (with power 4Kw). 3.2、Screen exchanging period is 1.5 second per time. 3.3、Screen-exchanging plate is made out of 45steel or 40Cr and heat-treated. The surface is polished to prevent from material leakage. 3.4、Motor power of the hydraulic station is 4Kw, accumulator 25L, capacity 31.5Mpa pressure. Be able to be operated manually and electrically from 5m distance. 3.5、Melt pipe is made out of 45# steel. The interior surface is chrome plated and polished. Its flow channel is smooth without dead space. The melt pipe and the 200 extruder are connected by bolt or welded. Heating of the melt pipe is of ceramics heater. All the connection positions should be of enough space for dismantle and install the bolts, and are sealed by red copper washer.

4、Spiral hopper and mixer, model: 1 T/H 4.1、It consists of mixer, feeder and hopper. 4.2、The feeding screw diameter is Ф155mm and feeding capacity is 1 T/25min. 4.3、Mixing is realized in a reciprocating up-and-down way. Its mixing screw’s diameter is Ф155mm, mixing period is 15minutes ( feeding period is 25 minutes) 4.4、Both the motor for mixer and that for feeder is of 2.2Kw, driven through belt. 4.5、There should be at least 3 observation windows and a hand hole (for exchanging of magnetic bracket) around the hopper. At the joint of hopper and water jacket a tetrafluoro sealing bush is used to protect from dust. 4.6、Alternatively,the asbestos sealing pad and dustproof plate made of soft PVC are used to seal. 4.7、There is a special supporting mechanism at the feeding part of the hopper to protect form vibration. 4.8、All the belt transmission devices have protective cover.

5、 Flatting mill, model: 1000×1600 5.1、It consists of pressing board and smooth plate, shelf, driving components and die supporter. 5.2、The specification of pressing board is 2000×1000×40mm. One is assembled at the top while the other is at the bottom. The two pieces are adjusted by master screw lifter with motor power of 2×1.1=2.2KW. 5.3、The pressing plate is made of polytetrafluoroethylene board of specification 1400x1350x5mm, one is assembled at the top while the other is at the bottom. 5.4、The shelf is welded by shaped steel No 14, die supporter is made of steel plate of 30 mm thick and adjustable bolt. 5.5、There is a switch to set the highest position when the upper pressing plate rises. There is also an emergency switch at the side plate (when switched on, the upper pressing plate is opened in no time). 5.6、The flatting mill is fastened by open-type helical lock.

6、First haul-off unit 6.1、Two groups haul off, each haul off power is 3 Kw, the helical gear worm gear and worm reducer is made by Zhejiang Tongli Factory. One transducer works separately. 6.2、Two groups of rubber rollers comprise the drawing rollers, transmitted by gear. The upper group is pressed actively. 6.3、The upper rollers are operated synchronously by worm gear and worm, the width of the roller is 1450mm and diameter 215mm, all are made out of rubber. 6.4、The shelf is made out of profile steel. 6.5、The protective roller and emergency switch are installed at the entrance for plate. Aside there is a protective cover.

7、Longitudinal cutting machine 7.1、 Totally two pieces of saw blades for cutting. 7.2、 This part may be installed between first haul-off unit and second haul-off unit. 7.3、 The maximum cutting thickness is 100mnm. 7.4、Power of the cutter is 1.1Kw, there is dust collector here, fan power 1.5Kw.

8、Second haul-off unit 8.1、Two rubber rollers of the same specification with those of the first haul off unit. 8.2、The power of reductor which made by Zhejiang Tongli Factory is 3Kw, driven also by chain, frequency conversion inverter. 8.3、The shelf is welded by profile steel. It’s clamped by master screw. 8.4、The upper and the lower roller are all motivity roller, driven by gear, adjusted up and down by master screw. 8.5、Longitudinal cutting machine and Second haul-off unit are in the same unit.

9、Cooling roller shelf 9.1、Total length 18m 9.2、Roller is made out of Aluminum, specificationФ70×1450mm. 9.3、On the supporting rollers there is a mechanism that limits horizontal movement of plate. 9.4、The bolts for foundation adjustment are equipped. The adjustable distance is the center height ±80mm.

10、Cross cutting machine 10.1、Cutting is done by saw type, saw specification Ф450×30×3mm. 10.2、Power 3Kw, rotational speed 2800rpm, moving motor power 0.75Kw, driven by chains 10.3、The movement of the carriage is driven by beeline bear. 10.4、Cutting length is controlled by photoelectric switch and the cutting length can be set freely. 10.5、Clamped by pneumatic, the max cutting thickness 100mm. 10.6、Conveyer is after the Cross cutting machine. 10.7、Motor power of the conveyer is 0.37Kw.

11、Stacker and transmission machine The stacker is welded by shaped steel and protected by zinc plated panel. Its specification is 2.4m ×1.2m×0.6m. 12、Die can make 30-80mm thick, 600-900mm wide product. The die is made out of 40Cr or 3Cr13 with the clothes hanger-type flow channel, the interior surface is chrome plated. Temperature control 8 zones, heating power about 3Kw each.

13.、Controlling cabinet for extruder 13.1、It consists of power controller, temperature controller and etc. 13.2、The main motor is controlled by EUROTHERMO (from UK) speed regulator or an ABB (from Swede) one. 13.3、Temperature controllers for barrel, adapter and mesh-exchanger are RKC(or Fuji)meters from Japan and the thermocouple is used for temperature sensor. 13.4、Relay is made by Suzhou Siemens AC relay factory. The voltage of heater is 380v. 13.5、Both pressure and temperature of melt are controlled by meter form Chengdu Xianda. One set is settled before the mesh-exchanger and the other—before the die. 13.6、The other electric components are l from high-grade domestic or joint company, including air switches from LG, buttons from Shanghai Tianyi and the contactor from Suzhou Siemens. 13.7、The controller box has good ventilation to ensure fine operation of electric appliance. 13.8、The electric control cabinet needs a supporter of 150-200mm. 13.9、Measures should be taken to prevent from the motor from over voltage, the main motor from over loading, the motor for pump from over voltage (in that case the plunger pump must be shut down).

14、Controlling cabinet of downstream equipment 14.1、The controlling cabinet for downstream equipment consists of the operation panel and handle of flatting mill, inverter cabinet of haul off units, operation cabinet of cross cutting machine, transducer cabinet of auxiliary equipment, operational box of feeding system, remote controller of plunger pump, remote controller of hydraulic station. 14.2、To guarantee safe operation, the operation panel of the flatting mill is handy type or remote control type. And there are two emergency scram buttons. 14.3、Inverter cabinet for haul off unit consists of 3 inverters (imported Danfoss) and PLC, controlling the first haul off and the second haul off so that the haul off speeds can be precisely matched. The motor of plunger pump is equipped with a 4Kw Danfoss transducer. 14.4、Operation cabinet of cutting machine mainly controls the cutting program to insure cutting precision. 14.5、The wire of the motors is interference-resistant shielding wires and compensation wires. 14.6、The transducer is made by Danmark Danfoss.

15、Die temperature controller heating power 6 KW, cooling method water cooling.

16、Foam agent injection system 16.1、High-pressure plunger pump: 63l/h. The power of motor: 4Kw. Danfoss transducer. 16.2、High voltage wires and joints are form Yuanheng in Taiwan. The energy storage in made in 16.3、The maximal pressure is 50Mpa. 16.4、The plunger pump is equipped with ordinary sealing outfits. 16.5、The plunger pump is made in Hangzhou Zhijiang petrochemical equipment Co., Ltd. 16.6Shockproof supporter is equipped.

Ⅲ、AUXILIARY EQUIPMENT 1、groove machine 2、up and down surface roughing machine 3、crusher 3.1、FT215A crusher with the power of 7.5Kw, equipped with 4Kw feeding blower fan. One blade and screen are provided as spare parts. 3.2、FT225A crusher with the power of 18.5Kw, equipped with 5.5Kw blower fan for material transferring. One blade and screen are provided as spare parts.

Ⅳ、LIST OF SPARE PARTS 1. 165 Heating circle for 135 extruder One set 2. 200Hating circle for 150 extruder One set 3. Electro-magnetic valve with the water medium 1 Piece 4. Thermocouple 1Pieces 5. Installation instrument for extruder One set for each 6. 1 1/2 Rotation joint 2 pieces 7.Ф8 Gas pipe 5 meters 8. Rubber pressing block for cutter 1 Piece 9. Magnetic bracket for hopper 1 Piece 10. Temperature controller 1 Piece 11. Photoelectric switch 1Piece 12. 20A currency meter 1 Piece 13. 40A currency meter 1 Piece 14. Two-position electromagnetic valve 1 Piece 15. Speed regulating button for extruder 1Piece 16. RKC meter 1 Piece 17. Heating stick for die 1 Piece 18. Heating stick for mesh-exchanger 1Piece 19. Tee and through joints of high pressure wires One set for each 20. high pressure injection accumulator 1 piece 21. Multihole plate of mesh-exchanger 1Set Ⅴ、Others Color is based on blue, yellow and white or according to the customer’s requirement. the full set English operation manual and electrical route drawing. After contract becomes effective, we will provide outline of machine. all mark, indication lamp and button apply English. When machine arrives factory, the supplier will send 2 testing engineers to assist installment and test. The buyer bears boarding and lodge and traffic fee and round-trip ticket fee.

|