Cung cấp dây chuyền sản xuất xốp XPS công nghệ CO2

|

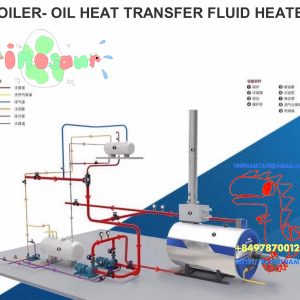

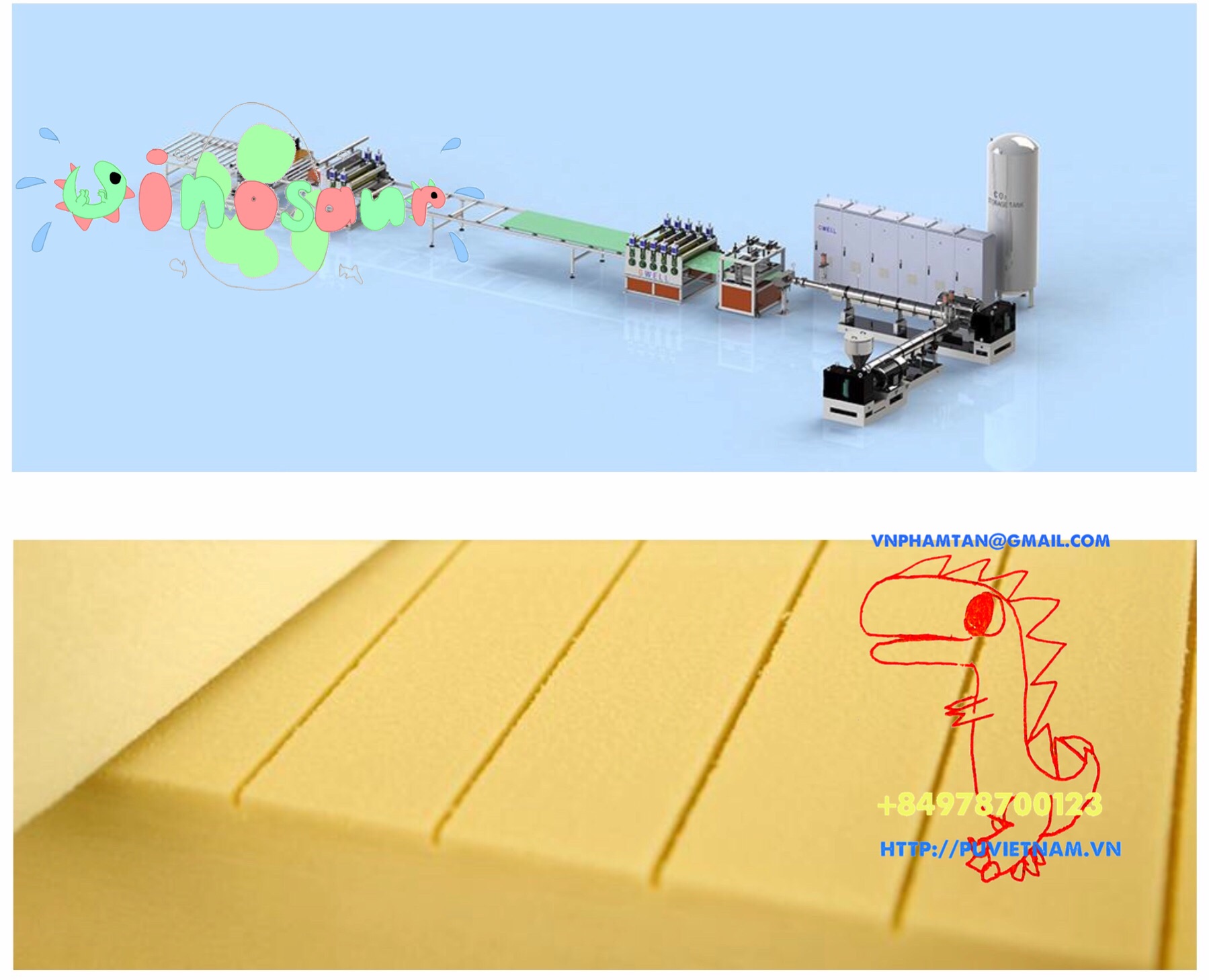

Việt Nguyên Co.,Ltd chuyên cung cấp các dòng máy công nghiệp sản xuất xốp XPS dùng trong sản xuất panel cách nhiệt, xốp XPS sản xuất thùng xe đông lạnh, xốp XPS cắm bông sử dụng công nghệ trợ nở thân thiện môi trường sử dụng CO2.

XPS FOAM BOARD PRODUCTION LINE

SJ1200 XPS LINE TECHNICAL AGREEMENT PRODUCT SPECIFICATION: l WIDTH : 600-1200MM l THICKNESS: 30-100MM l l l MATERIAL: PS (BASF foam grade: GPPS158K) l FOAM AGENCY: CO2(Carbon doxide) I、SUPPLY RANGE: 1、SJ135 Single screw extruder: One set 2、SJ150 Single screw extruder: One set 3、Hydraulic screen ex-changer: One set 4、Spiral hopper and mixer, model: 1 T/h One set 5、1000×1600 Flatting mill, model: 1000×1600 One set 6、First haul-off unit One set 7、Longitudinal cutting machine One set 8、Second haul-off unit One set 9、Cross cutting machine One set 10、Cooling roller shelf One set 11、Stacker and transmission unit One set each 12、Die Two sets 13、Controlling cabinet for main extruder One unit 14、Controlling cabinet for downstream equipment One set 15、Temperature controller for die One set 16、Foam agent injection system One set 17、Auxiliary equipment 18、List of spare parts

|

Ⅱ、TECHNICAL CONFIGURATION

Ⅱ、TECHNICAL CONFIGURATION