Cung cấp dây chuyền panel EPS/Rockwool ngàm vuông

|

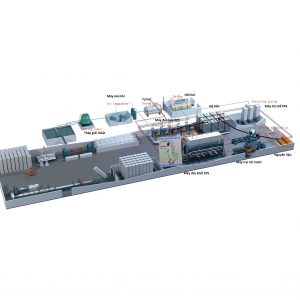

Việt Nguyên Co.,Ltd cung cấp dây chuyền sản xuất panel EPS/XPS/ROCKWOOL ngàm vuông chuyên dụng SANDWICH PANEL PRODUCTION LINE

|

· ROOF OF PROFILE: (1200-1050mm)—980mm

The Sandwich Panel Production Line is composed of four (6) main sections, such as, roof roll former, steel un-coiler, eps loading bed & edge milling machine, sandwich panel laminator,automatic length counting panel cutter,rolling table.

The Sandwich Panel Production Line is composed of four (6) main sections, such as, roof roll former, steel un-coiler, eps loading bed & edge milling machine, sandwich panel laminator,automatic length counting panel cutter,rolling table.

The production line is 40000mm x 4000mm x 2350mm.

III . The Main Parts Of The Production Line

1. Roof Roll Former:1Pcs.

· Stands of Forming: 14

· Roller Diameter: 72mm

· Material model of Roller: 40#

· Thickness of Coated Chrome: 0.05m~0.06mm

· Forming Speed: 0~6.0m/minute

· Thickness of steel coil: 0.2mm~0.6mm

· Motor Power: 2.7kw

2. Steel Un-coiler: 1set.

2. Steel Un-coiler: 1set.

· Width of coil: ≤ 1250mm

· Weight of coil: ≤ 6 mt

3. EPS/ROCK WOOL Loading Bed and milling machine 1Set.

3. EPS/ROCK WOOL Loading Bed and milling machine 1Set.

· Feeding frame Length: 4m

· Feeding speed: 0~6m/min

· EPS foam milling depth and thickness: adjustable

4. Wall and roof square lock forming machine: 1Set.

4. Wall and roof square lock forming machine: 1Set.

· Rolling forming stands: 8pcs.;

· Forming Roller material: GCr15 ;

· Width sliding range: 900-1200mm;

· Sliding bearing type: Linear.

5. Sandwich Panel Laminator: 1Pcs.

5. Sandwich Panel Laminator: 1Pcs.

5.1 Laminating Press Roller/ Prensa de rodillos de laminacion:

5.1 Laminating Press Roller/ Prensa de rodillos de laminacion:

· Rubber roller Diameter: 150mm;

· Thickness of composite rubber layer: 10mm;

· Quantity of rollers: 16 pairs

5.2 Glue Spraying Device:

5.2 Glue Spraying Device:

· Quantity of pump: 4 sets;

· Motor Power: 0.37 kw X 4;

· Flow volume of glue: 0 – 0.4 kg per pump;

· Flow volume adjusting: by inverter;

· Scale of glue: randomly;

· Glue dropping pipe: stainless steel

5.3 Glue Uniformity Device/ Pegamento uniformidad dispositivo :

5.3 Glue Uniformity Device/ Pegamento uniformidad dispositivo :

· Speed of sweeping : 80 times/min.

· Motor Power: 0.5kw x 3

5.4 Plastic Film Applying Device:

5.4 Plastic Film Applying Device:

· Conical push pin by wheel adjusting

5.5 Dust Suction For EPS/ROCK WOOL Waste :

5.5 Dust Suction For EPS/ROCK WOOL Waste :

· Type of suction: Blowing fan and collecting bag;

· Motor Power: 2.2 kw

6. Automatic Length Counting Panel Cutter: 1set.

6. Automatic Length Counting Panel Cutter: 1set.

· Type of Cutting: Blade and circle Saw

· All motor Power: 1.5 kw x 2

· Cutting thickness range: 40mm – 120mm

· Push piston stroke : 1800mm

· Auto control electrical device: Touch screen and PLC

|

Video chạy máy sản xuất panel EPS ngàm Vuông

|