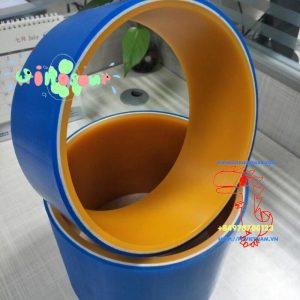

Dây chuyền sản xuất ống TPU

|

Vinosaur Việt Nguyên.,Co Ltd Chuyên cung cấp các giải pháp sản xuất các sản phẩm dân dụng và công nghiệp.

Ống TPU sử dụng phổ biến trong ngành y tế, sử dụng làm ống khí chuyên dụng, ống TPU truyền mực in. TPU được ưa chuộng trong các ngành đòi hỏi yêu cầu cao về độ bền, đặc tính phù hợp trong y hoc.

TPU 小管生材产线配置

|

SJ45/25 single screw extruder and die–1unit

1. 机架 rack

1. 机架 rack

采用型钢及板材焊接而成,并经回应力处理,有较高的钢性,变形小。

Adopt section steel and plate welding with heat treatment for strength;

2. 齿轮箱 gearbox

2. 齿轮箱 gearbox

产品设计采用ZBJ19009-88 所规定的技术规范,齿轮和轴类零件采用高强度合金钢材质,齿轮精度GB10095-88,6 级,齿面硬度HRC-6,在输出轴端配置有超规格的推力轴承,承受螺杆的后推力,轴承和油封等主要标准件皆采用国内优质产品,整机承载能力较高,传动平稳,噪音低,效率高。

The product design adopts the technical specification stipulated by ZBJ19009-88, the gear and shaft parts are made of high strength alloy steel material, the gear precision is GB10095-88,6 grade, and the tooth surface hardness HRC-6, has super specification thrust bearing at the end of the output shaft to bear the rear thrust of the screw. Main standard parts such as bearings and oil seals are made of high quality with high bearing capacity, with stable transmission and low noise and high efficiency.

l 减 速 比 :12.5:1 Reducer ratio: 12. 5: 1

l 输入功率:11KW Input power: 11kW

l 采用硬齿面磨削齿轮,低噪高寿,运行可靠

Gear grinding with hard tooth surface, low noise and high durability, reliable working;

l 油浸润滑系统

Oil-immersed lubrication system

3. 料筒及螺杆

3. 料筒及螺杆

Barrel and screw

l 料筒及螺杆材料均为 38CrMoAlA 优质氮化钢

The materials of the barrel and screw are 38CrMoAlA high quality nitrided alloy steel.

l 氮化层深度:0.5-0.7mm,氮化硬度:螺杆 900HV,料筒 930HV

Nitriding layer thickness: 0.5-0.7mm, hardness: screw 900HV, barrel 930HV

l 螺 杆 直 径 :45mm Screw diameter:45mm

l 螺 杆 长 度 :1125mm Screw length: 1125mm

l 螺 杆 转 速 :0~75rpm Screw speed: 0 ~75rpm

l 螺杆螺棱表面粗糙度:0.4um

Screw screw surface roughness: 0.4um

l 料筒内表面粗糙度:0.4um Inner surface smooth: 0.4um

4. 加热系统(加热器) Heating system (heater)

4. 加热系统(加热器) Heating system (heater)

l 机筒采用 3 组加热器,机头另备 2 区加热器

Three groups of heaters of barrel, and 2 zone heaters on the mold;

l 加热电源:3-AC380V,50HZ,

Heating power supply: 3-AC380V / 50HZ,

l 加热器外覆不锈钢安全罩

Stainless steel safety cover for heater

5. 冷却装置

5. 冷却装置

Cooling unit

l 机筒用 3 组离心风机冷却,320W/区

Three sets of centrifugal fans for cylinder cooling unit 320W / area

l 风机电源:3-AC380V,50HZ,

Fan power supply: 3-AC380VX 50HZ,

6. 主电机

6. 主电机

Main Motor

l 电机功率:7.5KW,

Motor power: 7.5 KW,

l 电机与主机一体安装

Motor and mainframe installation

l 电机同步转速 1500rpm

Synchronous speed of motor 1500rpm

7. 加料斗:

7. 加料斗:

Hopper:

l 不锈钢圆形料斗,

l Stainless steel round hopper,

8. 机头联接法兰: Connection flange:

8. 机头联接法兰: Connection flange:

l 锻 45#钢精加工内衬镀硬铬而成,与机头内六角螺栓联接

l Forged 45# steel machined, made of hard chromium, connected with hexagonal bolt in die head

l 表面发黑处理

l Surface blackening treatment

9. 电气控制柜:

9. 电气控制柜:

Electrical control cabinet:

l 电源:3-AC380V,50HZ

Power source: 3-AC380VX 50HZ

l 变频调速器:丹弗斯集团海利普变频器

Variable frequency Danvers group Halip inverter

l 温度控制:5 区,CHB 数字式温控仪

Temperature control: 5 area CHB digital temperature controller

l 独立电控柜

Independent electronic control cabinet

II. 冷却定型水槽

II. 冷却定型水槽

Water cooling Channel–1unit

l 真空泵功率:2.2kw

Vacuum pump power: 2.2 kw

l 水泵功率:2.2KW Pump power: 2.2 KW

l 移动电机功率:0.55kw Mobile motor power: 0.55kw

l 箱体材料:不锈钢

Box material: stainless steel

l 长度:2400mm Length: 2400mm

III. 皮带式牵引机

III. 皮带式牵引机

Belt type tractor–1unitl 电机功率为 0.75KW Motor power is 0.75KW

l 采用变频器进行无级调速

Stepless Speed Regulation with Inverter

l 牵 引 速 度 :2~15m/min Traction speed: 2~15m / min

IV. 收卷机

IV. 收卷机

WINDER–1unit

l 减速机:SWP80-1 Reducer: SWP80

l 传动件:6 分双排链

Transmission: 6” double chain

l 主轴件:Φ85 圆钢

Spindle:Φ85 round steel

l 排线器:GP30 光杆排线器

Wire layer: GP30 rod wire straightener

l 收卷最大直径:600mm

Maximum winding: 600mm diameter

l 收 卷 速 度 :0.5-15m/min Winding speed: 0.5-15m/min

video dây chuyền sản xuât ống TPU