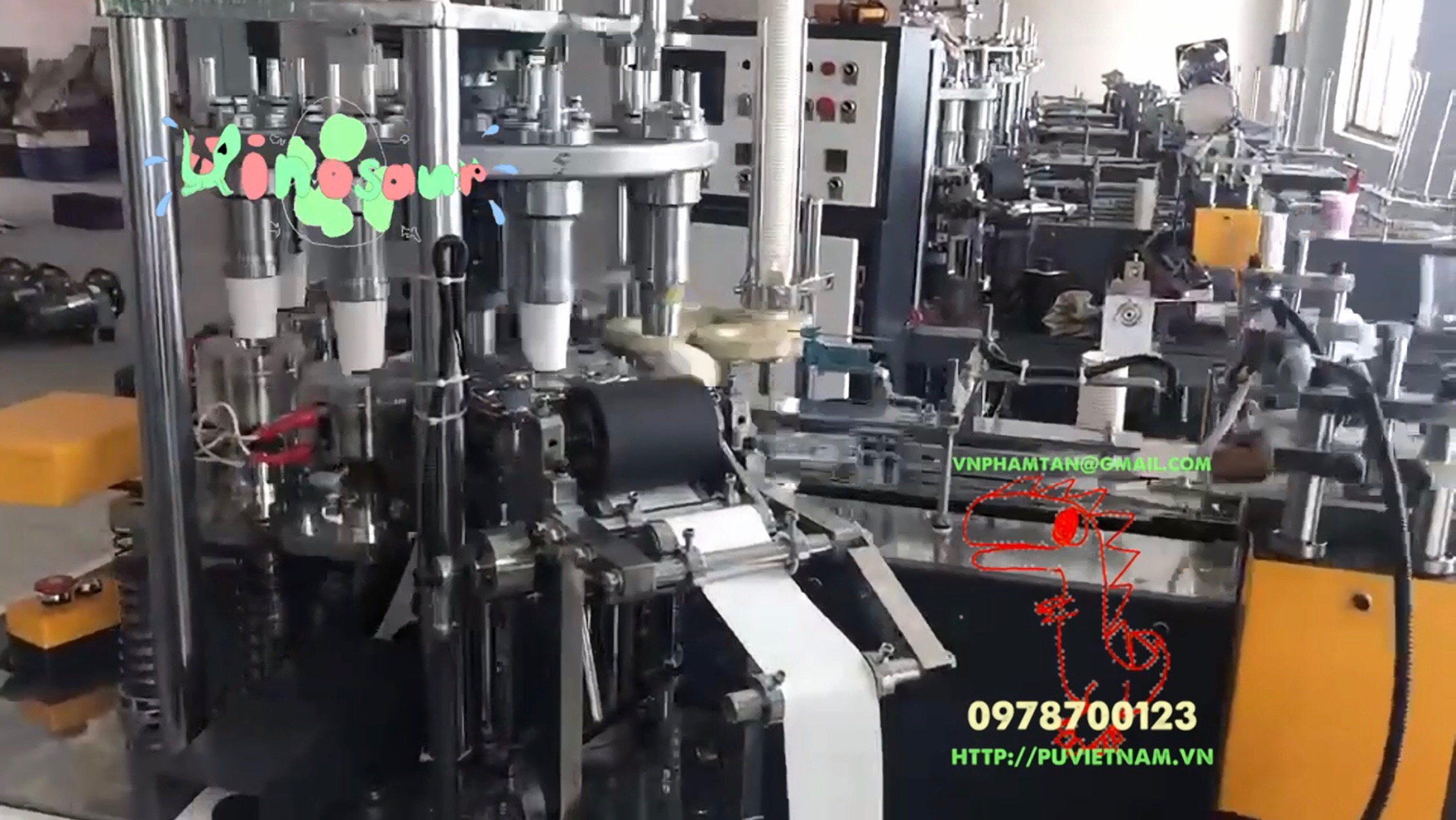

Cung cấp dây chuyền sản xuất cốc giấy, ly giấy bảo vệ môi trường

|

Việt Nguyên Co.,Ltd Cung cấp dây chuyền sản xuất ly giấy, cốc giấy, tách giấy đựng thực phẩm, bán các dòng máy sản xuất ly giấy đựng trà sữa, cốc giấy đựng cafe…

|

|

No. |

Model |

ZV-ZB12 |

|

1 |

Speed | 60-80 pcs/min |

|

2 |

Cup size |

Top Diameter: 60mm(min)-115mm(max)

Bottom Diameter: 40mm(min)-85mm(max) Height: 50mm(min)-180mm(max) |

|

3 |

Raw material | 135-450 GRAM |

|

4 |

Configuration | ULTRASONIC & HOT AIR SYSTEM |

|

5 |

Output | 12KW,380V/220V,60HZ/50HZ |

|

6 |

Air compressor | 0.4 M³/Min 0.5MPA |

|

7 |

Net weight | 1.8 TONS |

|

8 |

Dimension of machine | 2500×1800 ×1700 MM |

|

9 |

Dimension of cup collector | 900 ×900 ×1760 MM |

Product Application

Product Application